Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

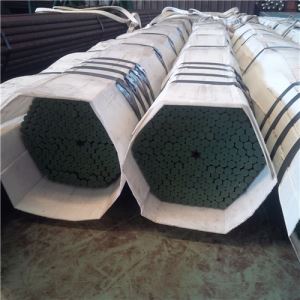

ASTMA A53 Black and Hot Dipped Zinc Coated Welded and Seamless Steel Pipe

Scope:

Covers Seamless and Welded, Black and Hot-Dipped Galvanized nominal (average) wall pipe for coiling, bending, flanging and other special purposes and is suitable for welding. Continuous-Welded pipe is not intended for flanging. Purpose for which pipe is intended should be stated on order.

Materials and Manufacture:

The steel for both seamless and welded pipe shall be made by one or more of the following processes: open-hearth, electric furnace, or basic-oxygen. The weld seam of electric-resistance welded pipe in Grade B shall be heat treated after welding.

Chemical Requirements:

|

Type S |

Type E |

Type F |

||||

|

(electric- |

(furnace- |

|||||

|

Grade A |

Grade B |

Grade A |

Grade B |

Grade A |

||

|

Carbon max. % |

0.25 |

0.30 |

0.25 |

0.30 |

0.3 |

|

|

Manganese % |

0.95 |

1.2 |

0.95 |

1.2 |

1.2 |

|

|

Phosphorous, max. % |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

|

|

Sulfur, max. % |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

|

|

Copper, max.% |

0.40 |

0.40 |

0.40 |

0.40 |

0.4 |

|

|

Nickel, max. % |

0.40 |

0.40 |

0.40 |

0.40 |

0.4 |

|

|

Chromium, max. % |

0.40 |

0.40 |

0.40 |

0.40 |

0.4 |

|

|

Molybdenum, max. % |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

|

|

Vanadium, max. % |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

|

Hot-Dipped Galvanizing:

Sets standards for coating of pipe with zinc inside and outside by the hot-dipped process. Weight of coating must not average less than 1.8 oz. per square foot and not less than 1.6 oz. per square foot.

Permissible Variations in Wall Thickness:

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

Permissible Variations in Weights per Foot:

Plus or minus 10%

Tensile Requirements:

|

|

Seamless and Electric-resistance-welded |

Continuous-Welded |

|

|

|

Grade A |

Grade B |

|

|

Tensile Strength, min., psi |

48,000 |

60,000 |

45,000 |

|

Yield Strength, min., psi |

30,000 |

35,000 |

25,000 |

Hydrostatic Testing:

Hydrostatic inspection test pressures for plain end and threaded and coupled pipe are specified. Hydrostatic pressure shall be maintained for not less than 5 seconds for all sizes of seamless and electric-resistance-weld pipe.

Mechanical Tests Specified:

Tensile Test -- Transverse required on ERW for NPS 8 and large. Sending Test (Cold) -- STD and XS-NPS 2 and under XXS-NPS 1 1/4 and under.

|

|

Degree of Bend |

Diameter of Mandrel |

|

For Normal A53 Uses |

90 |

12 x nom dia. of pipe |

|

For Close Coiling |

180 |

8 x nom dia. of pipe |

Flattening Test -- NPS 2 and larger STD and XS. (Not required for XXS pipe.)

Lengths:

| Standard Weight | |

|

Single Random -- 16' - 22'. 5% may be jointers. If Plain Ends -- 5% may be 12' - 16'. |

|

|

Double Random -- Shortest Length 22', minimum average for order 35'. |

|

|

Extra Strong and Double Extra Strong |

|

|

Single Random -- 12' -22'. 5% may be 6' - 12'. |

|

|

Double Random (XS and lighter) -- Shortest Length 22', minimum average for order 35'. |

|

|

Lengths longer than single random with wall thicknesses heavier than XS subject to negotiation. |

General Information:

| Couplings -- Applied handling tight. Couplings, 2" and smaller straight tapped, other sizes taper tapped. | |

|

Thread Protection -- Applied to pipe 4" and larger. |

|

|

End Finish (unless otherwise specified) -- |

|

|

STD or XS, or wall thicknesses less than 0.500 in. (excluding XXS): Plain and beveled |

|

|

All XXS and wall thicknesses over 0.500 in.: Plain end square cut. |

a53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless1

Diameter & Tolerance:

For pipe ≤ NPS 11⁄2 [DN 40], the outside diameter at any point shall not vary more than 1⁄64 in. [0.4 mm].

For pipe ≥NPS 2 [DN 50], the outside diameter shall not vary more than ±1%.

Galvanized

1), Zinc: The zinc used for the coating shall be any grade of zinc conforming to Specification B 6

2), Weight of Coating—The weight of zinc coating shall be not less than 1.8 oz/ft2[0.55 kg/m2] as determined from the average results of the two specimens taken for test in the manner prescribed in 19.5 and not less than 1.6 oz/ft2[0.49kg/m2] for either of these specimens. And testing the weight of zinc according to ASTMB90

Common Uses:

- Low pressure systems

- Structural applications

- Mechanical components

- Bollards

- Casing

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com