Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

Steel Knowledge

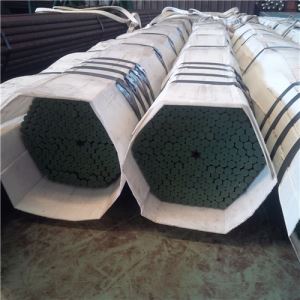

Insulation tube is made of steel pipe, glass fiber reinforced plastic jacket, FRP shell, which is characterized by: also includes high temperature insulation layer, lubrication layer, elastic seal. The utility model effectively solves the problem of heat preservation, sliding lubrication and waterproofing of the prefabricated direct buried insulation pipe in the high temperature heat transfer of 130 ℃ -600 ℃ in the urban central heating.

High temperature prefabricated buried insulation tube mainly consists of four parts.

(1) working steel pipe: According to the technical requirements of the transmission medium were used seam steel pipe, seamless steel pipe, double-sided submerged arc welded steel pipe.

(2) insulation layer: the use of rigid polyurethane foam.

(3) protective shell: the use of high-density polyethylene or glass steel.

(4) leakage alarm line: the manufacture of high-temperature prefabricated buried insulation tube, near the insulation layer in the steel pipe, buried with an alarm line, once the pipeline somewhere leakage, through the alarm line conduction, can be in the special detection instrument On the alarm and show the exact location of the leak and the size of the leakage in order to inform the maintenance personnel to quickly deal with the leakage of the pipe section to ensure the safe operation of the heating network.

High Temperature Prefabricated Buried Insulation Tube - Advantages

1 Reduce the project cost.

According to the relevant departments to estimate, double-pipe heating pipe, under normal circumstances can reduce the project cost of 25% (using glass fiber reinforced plastic layer) and 10% (using high-density polyethylene to do protective layer) around.

2 low heat loss, energy conservation.

The corrosion protection grade of the steel pipe casing shall be determined according to the local soil corrosive grade. When the corrosiveness level of the soil is buried in the soil, the corrosion degree should be considered especially when the corrosion degree of the soil is moderate. When the soil corrosion degree is moderate, the corrosion degree should be considered. When the soil corrosion degree is low When the anti-corrosion grade should be considered ordinary level. So the design must be clear pipeline section of the soil corrosion level, in order to corrosion grade optimization. Direct protection of the cathodic insulation pipe in the metal corrosion protection process, is a kind of electrochemical protection. Unlike other direct-buried thermal insulation processes, it imposes a current on the protected metal body so that the electrode potential of the metal being protected is negatively shifted, causing the metal to lose its tendency to spontaneously change from atomic to ion Fundamentally inhibited the occurrence of corrosion. But this process must be carried out in the electrolyte, so buried steel pipe is very suitable for cathodic protection. The cathodic protection is complementary to the anti-corrosion layer of the buried pipe itself, and the presence of the coating can greatly reduce the current consumed by the cathodic protection, while the cathodic protection can compensate for the inadequacy of the integrity of the coating, and thus in terms of safety and economy To achieve the perfect combination, is currently recognized as the best anti-corrosion program.

During the Ching Ming holiday, the sheet market fell first and then stabilized, and the merchant feedback was poor in the near future. Raw material billet fell deep before the holiday, the recent slight correction of 50 yuan / ton, affected by the billet, the plate market a little boost, but the rebound is still under pressure. 5 days after the first working day, the market rebound pressure is still large, is expected to plate market or mainstream stability, part of a slight increase of 10-20 yuan / ton. Weekly strip steel market pulled up slightly, narrow narrow up 30-40 yuan / ton, the overall transaction in general, individual can be. 232 series of steel steadily up 20, the general market transactions. Steel mill unilateral pull up means more. Billet itself straight hair goods in general, the spot 2900-2910 yuan / ton out of the library, the overall performance is acceptable. Manufacturers still have a lot of willingness. During the Ming and Qing Dynasties, the structural steel market steadily weak, mainly the preganglionic billet and steel prices down the price down further down the popularity. While the enthusiasm of the downstream procurement is not high, the market a small adjustment of shipping prices. The current market part of the main offer, the main intention to do further adjustments after the holiday. 5 days after the first trading day, the overall wait-and-see atmosphere or relatively strong, the market is expected to stabilize the main part of the adjustment.

Recently, coal, steel industry and "fire" the. National Bureau of Statistics released data show that the first two months of this year, coal mining and washing industry prices rose an average of 39.0% year on year, ferrous metal smelting and rolling processing industry prices rose an average of 38.9% year on year. Benefit from coal prices, steel prices rose rapidly, coal, steel industry efficiency has improved significantly. The first two months of this year, coal mining and washing industry from the same period last year to 438 billion loss of profits, ferrous metal smelting and rolling processing industry, the total profit increased by 21.1 times. With the market situation improved and prices rise, coal, steel to work capacity also appeared in some new situations and new problems. For example, some places and enterprises have been waiting, wait and see mood, part of the enterprise itself to the production capacity of the decline in capacity to increase the difficulty of withdrawal. Although last year to achieve the initial victory, but still to long-term production capacity. At present, the steel, coal industry, a serious excess capacity, oversupply pattern and there is no fundamental change in the industry capacity utilization has not rebounded to normal levels. Once the capacity to work down, the industry will once again fall into the bottom, to reproduce the market downturn two years ago, the price fell, the huge losses of the enterprise scene. The confidence and determination to yield can not be relaxed. In fact, steel, coal two industry situation improved, precisely reflects the effectiveness of production capacity. In this regard, the majority of enterprises are deeply experienced. According to 145 private iron and steel enterprises statistics, 2016 annual sales growth of 11%; profits of 40.1 billion yuan, while the loss of 4.4 billion yuan a year earlier.

Hot rolling is a method of thermal press working in which the metal tube is continuously deformed by the gap between the rolls. Normally, the rolls are divided into two types: one is two rolls, one is three rolls, Adjust the gap between the rolls to change the outer diameter of the tube. According to the different production methods, can be divided into three categories: (1) hot-rolled seamless steel pipe (2) welded steel pipe (3) cold drawn or cold processing tube. Hot-rolled seamless steel pipe sub-general steel pipe, low, medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking pipe, geological pipe and other steel pipe. Hot-rolled seamless steel pipe Advantages: coarse grains affected by pressure into fine grains, thus changing the mechanical properties; as-cast organization loose, pores, air bubbles after hot rolling compaction, density increases; hot rolling longer grain , Forming fibrous tissue. Disadvantages: hot rolling will appear stratification phenomenon, stratification can make the steel along the direction of the performance of the weakened; hot rolled products on the thickness of the process is difficult to control, which is difficult to solve many manufacturers problems.

General seamless steel pipe production process can be divided into cold drawing and hot rolling two, cold-rolled seamless steel pipe production process is generally more complicated than hot-rolled, tube first to be three-roll rolling, after extrusion to be carried out Sizing test, if the surface is not responding to the crack after the tube to go through the cutting machine for cutting, cutting into a length of about one meter of the blank. And then into the annealing process, the use of acidic acid for acid pickling, pickling should pay attention to whether the surface of a large number of foaming produce, if there is a large number of blistering that the quality of steel pipe can not meet the corresponding standards. The appearance of cold-rolled seamless steel pipe is shorter than hot-rolled seamless steel pipe, cold-rolled seamless steel pipe wall thickness is generally smaller than the hot-rolled seamless steel pipe, but the surface looks thicker than thick-walled seamless steel pipe, the surface is not too More rough, caliber no too much burr.

Related News

- Spring steel standards...

- National standard of bearing steel...

- Seamless steel tube series...

- Welded pipe standard...

- How to choose a water supply network in the valve...

- 12cr1movG high-pressure alloy tubes what are the specific cl...

- Welded pipe standard...

- What is a pipe?...

- What is a coated steel pipe?...

- Specifications and appearance quality of boiler tubes...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com