Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

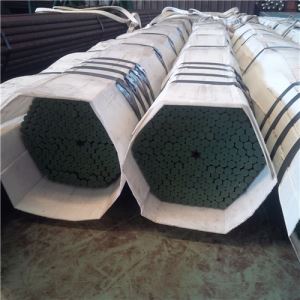

The stainless steel tube has the longest service life. From the analysis of the use of stainless steel in foreign countries, the service life of stainless steel pipes can reach 100 years, at least 70 years, as long as the building life.

One of the most prominent advantages of stainless steel tubes is its excellent corrosion resistance, which is best in all kinds of tubing. Because stainless steel can be deactivated with oxidants, Stainless Steel Pipe and Tube the surface forms a tough dense chromium-rich oxide protective film Dr2o3, effectively preventing the further occurrence of oxidative reaction. and other metal pipes, such as galvanized water pipes, copper tube passivation ability is very small, this is galvanized pipe copper tube corrosion resistance is far less than the key reason for stainless steel pipe. Stainless steel will not be as homogeneous as carbon steel corrosion, Stainless Steel Pipe and Tube use without protective coating, stainless steel pipe, the chemical composition of the water is not limited, because stainless steel in a variety of oxygen content, temperature, ph and hardness of water has a good corrosion resistance; stainless steel pipes can withstand a high flow rate, even if the flow rate is greater than 40 m/s, still maintain very low corrosion rate, no more than 0.003 mm/year, particularly suitable for high-rise water supply. Stainless steel generally does not occur local corrosion, 304 stainless steel can withstand the chloride content of 200ppm, 316 stainless steel can withstand the chloride content of up to 1000ppm, this conclusion based on exposure to experimental data and has been used to confirm the experience. The thermal expansion coefficient of stainless steel tube is similar to that of copper tube, which is 1.5 times times that of ordinary steel pipe, which has the characteristics of slow shrinkage and contraction compared with stainless steel tube.

The thermal conductivity of the stainless steel tube is 1/25 of the copper tube, which is 1/4 of the ordinary steel pipe, especially suitable for hot water transportation. The most commonly used stainless steel in the water industry is 316 and 304 stainless steel, Stainless Steel Pipe and Tube which can satisfy most water treatment and transport conditions.

Stainless steel tube Due to excellent mechanical properties, can withstand a high water pressure, up to 10Mpa, especially for high-rise water supply.

With the continuous rise of buildings, many buildings in the construction process will be used in stainless steel pipe, some stainless steel pipe in the scaffolding, some stainless steel pipe in the family's outlet, in short, according to the use of different, its model is not the same. But most people only know this stainless steel tube, Stainless Steel Pipe and Tube but do not know how it is produced, today we will give you a brief introduction to tell you how this stainless steel tube production, hope for those who want to buy stainless steel pipe friends some help.

(1) Stainless steel tube blank preparation. including stainless steel billets, stainless steel tube cutting (cut or gas cut), peeling repair, inspection, and high alloy stainless steel tube surface treatment (such as pickling) and Lending.

(2) Stainless steel tube billet heating. Usually in the annular heating furnace or inclined bottom type tube billet heating furnace, after the tube billet is generally after hot centering sent to the perforation process.

(3) perforation. The solid round steel is rolled into a hollow thick-walled stainless tube, Stainless Steel Pipe and Tube which is usually perforated by two or three-roll oblique mills. If the stainless steel billet is a ingot or a continuous casting billet, it can be punched on the hydraulic press, or punched through a rolling hole in a two-roll (longitudinal-rolling) pressure piercing-P. P. M. Mill.

(4) Rolling stainless steel pipe. In order to further reduce the diameter and reduce the wall of the hollow capillary tube, the capillary tube must be machined into a machine. For automatic rolling tube unit, after the rolling stainless steel pipe also after the whole machine.

(5) Stainless steel tube reheating and sizing. In order to finally obtain the required finished pipe, usually the waste pipe reheating, Stainless Steel Pipe and Tube and then on the sizing machine, reducer on, tension reducer on or on the expansion of the machine for processing, to obtain a variety of specifications of the finished stainless steel pipe.

(6) Stainless steel tube finishing, inspection and packaging of human library.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com