Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

The advantages of stainless steel tube are many, not only in the physical characteristics of the characteristics of wear and pressure, in the chemical characteristics of corrosion resistance, not easy to occur rust, and so on, the service life has a great, is widely used in construction, next, for everyone to introduce the advantages of stainless steel pipe.

Stainless steel pipe is a hollow round steel, mainly used in petroleum, chemical, medical, food, light industry, Stainless Steel Pipe and Tube mechanical instrumentation and other industrial pipelines and mechanical components. Stainless steel pipe is an economical cross-section steel, is an important product in the iron and steel industry, usually accounted for 8% of the total steel 16%, its application in the national economy is very wide, Stainless Steel Pipe and Tube itself is a kind of economical metal section steel, is an important component of efficient steel, especially in oil drilling, Smelting and transportation industry demand is larger.

Geological drilling, chemical engineering, construction industry, machinery industry, aircraft and automotive manufacturing, as well as boilers, medical devices, furniture and bicycle manufacturing are also required a wide range of stainless steel tubes. Because the stainless steel pipe has the hollow section, Stainless Steel Pipe and Tube thus suitable for the liquid, the gas and the solid transportation pipeline; At the same time, compared with the same weight round bar, the steel pipe has large sectional coefficient and flexural torsional strength, Stainless Steel Pipe and Tube so it also becomes an important material in all kinds of mechanical and structural structures. The structure and components controlled by stainless steel have a larger cross-section modulus than solid parts.

What are the advantages of stainless steel tube?

1, stainless steel pipe has excellent mechanical properties, superior wear resistance, thin surface and dense chromium-rich oxide film, so that the stainless steel pipe, including soft water in the quality of all have good corrosion resistance, even if the use of buried in good corrosion resistance. Rust steel pipe can withstand up to 30 m/s high speed water erosion, used in the High head power plant diversion stainless steel pipe, pipe mouth end water speed of up to 60 m/s, still has more than 100 years of service life.

2, stainless steel tube tensile strength is greater than $number mm, galvanized pipe is twice times, copper tube 3-4 times, PPR tube 8-10 times, and has good ductility and toughness, is conducive to saving water resources, appearance, clean, fashion, 100% recyclable, safe and hygienic performance, good temperature resistance, Stainless Steel Pipe and Tube Good insulation performance, inner wall smooth water resistance small, can be in the temperature of -270鈩-400鈩 long-term safe work, whether high or low temperature, will not precipitate harmful substances, material performance is quite stable.

3, stainless steel pipe insulation performance is 24 times times the copper pipe, reduce the heat loss, suitable for hot water transport, will not cause environmental pollution, Stainless Steel Pipe and Tube green environmental protection, conducive to sustainable development, and stainless steel scrap also has a great economic value, safe and non-toxic, non-corrosive and exudate, no odor or turbidity problems, will not cause two of the water pollution, Keep the water quality clean and hygienic, and ensure the safety of health.

Stainless steel tube Not only can play a very good supporting role, but also can carry on the long-distance liquid material, the gaseous material transmission, enhances the industrial production the efficiency, enables the people's life to be more convenient comfortable, the stainless steel tube cost-effective high, Stainless Steel Pipe and Tube applies in many domain infrastructure construction work, therefore in the life is common.

A high alloy steel capable of resisting corrosion in the air or chemically corrosive medium. Stainless steel tube is a beautiful surface and corrosion-resistant performance, Stainless Steel Pipe and Tube do not have to be plated

Color and other surface treatment, while playing stainless steel intrinsic surface properties, used in a variety of steel.

Stainless steel pipe is a hollow section of steel. Stainless Steel Pipe and Tube The thicker the wall is, the more economical and practical it is, the thinner the wall is, and the higher the processing cost of the stainless steel shaped pipe will be. Second, the process of the product determines its limitations, the general stainless steel tube precision: uneven wall thickness, low brightness in the tube, high cost, and inside the exterior there are hemp spots, black spots are not easy to remove, detection and shaping must be off-line processing. The stainless steel pipe produced by our company has good performance in high pressure, high strength, Stainless Steel Pipe and Tube and mechanical structure materials.

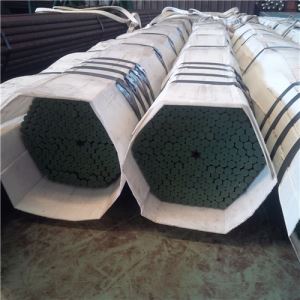

Types of stainless Steel tubes: Hot-rolled, hot extrusion and cold (rolled) stainless steel pipes are divided into rolling methods. According to the stainless steel tube elements of different parts of the semi-ferrite semi-martensite system stainless steel pipe, martensitic stainless steel tube, SOA system stainless steel pipe, austenitic-Tiesutie series of stainless steel tubes.

1: Hot-rolled (extruded seamless steel tube): round tube billet 鈫 heating 鈫 perforation 鈫 three-roll skew rolling, rolling or extrusion 鈫 off Tube 鈫 sizing (or reducing) 鈫 cooling 鈫 straightening 鈫 hydraulic test (or flaw detection) 鈫 Mark

2: Cold drawn/rolled seamless steel tube production methods than hot-rolled (extruded seamless steel tube) complex. The first three steps of the production process of stainless steel tube are basically the same, and the difference starts from the fourth step: after the round billet is emptied, Stainless Steel Pipe and Tube it should be preceded by annealing; After the annealing, the special acidic liquid is used for pickling; after pickling, the oil is oiled; and then, after a lot of cold drawing (cold rolling), the special heat treatment, the heat treatment, will be straightened. The stainless steel pipe is sent to the crack machine (or hydrostatic test) for internal flaw detection, if there are cracks, bubbles and other problems, will be detected.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com