Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

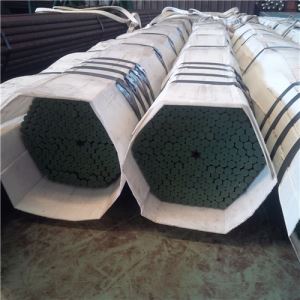

Carbon steel raw material is the round tube, the tube embryo to undergo the cutting machine cutting billets into lengths of about 1 m, and the conveyor belt to the furnace heats up. Billet is fed into a furnace heating temperature of about 1200 degrees Celsius. Fuel for hydrogen or acetylene. Furnace temperature control is the key issue. circular tube due to stress after piercing wear empty. Generally more common Mole is cone shaped roll piercer, this punch high production efficiency, product quality, and perforation of expanding capacity, can be worn a variety of steel grades. After the punch, round tube has been three-roll cross-rolling, rolling or extrusion. Extrusion pipe sizing. Sizing machine with a conical drill drilling of high speed steel embryo, forming tube. Outside diameter of the pipe inner diameter sizing machine drill bit length to determine. After sizing, it tube into the cooling tower through cooling water, after cooling, it tube, will be straightened. After straightening, it tube sent by conveyor belt to the crack detection machine (or pressure) for internal testing. If the pipe cracks, bubbles and so on, will be detected. Pipe inspection also strict hand-selected. After a steel pipe inspection, sprayed with paint numbers, specifications, production batch, and so on. And by crane into the warehouse.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com