Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

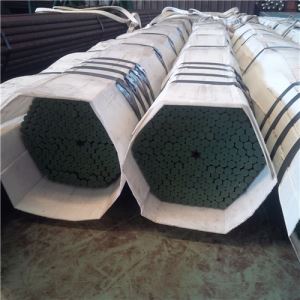

Carbon steel pipe, refers to the specific material of steel is carbon steel.

Carbon steel pipe is made of steel ingot or solid round bar through the perforated tube, and then by hot rolling, cold or cold made. Carbon steel pipe in China's steel industry has an important position.

Carbon steel pipe sub-hot rolling and cold-rolled (pull) steel pipe two categories.

Hot-rolled carbon steel pipe in general steel, low, medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking pipe, geological pipe and other steel pipe.

In addition to the general steel pipe, low pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking pipe, other steel pipe, but also includes carbon thin-walled steel pipe, alloy thin-walled steel pipe, not Rust thin-walled steel pipe, shaped steel pipe. Hot-rolled seamless pipe diameter is generally greater than 32mm, wall thickness 2.5-75mm, cold-rolled seamless steel pipe diameter can be 6mm, wall thickness to 0.25mm, thin tube diameter to 5mm, wall thickness is less than 0.25mm, Carbon Steel Pipe and Tube Cold rolling than the hot-rolled high dimensional accuracy.

General carbon steel pipe: is 10,20,30,35,45 and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB alloy steel such as hot-rolled or cold rolled. 10,20 and other low-carbon steel seamless pipe is mainly used for fluid pipeline. 45,40Cr and other carbon steel made of seamless pipe used to manufacture mechanical parts, Carbon Steel Pipe and Tube such as cars, tractors force parts. General use of carbon steel pipe to ensure strength and flattening test. The hot-rolled steel pipe is delivered in a hot-rolled state or a heat-treated state; the cold-rolled steel is delivered in a heat-treated state.

Carbon steel pipe material is round tube, round tube embryo to be cut through the cutting machine into a length of about 1 meter of the blank, and sent to the furnace by the conveyor belt heating. The billet is fed into the furnace for heating at a temperature of about 1200 degrees Celsius. The fuel is hydrogen or acetylene. Temperature control inside the furnace is a critical problem. Round tube billet after the pressure through the punching machine to wear empty. Carbon Steel Pipe and Tube Generally more common punching machine is a cone-shaped roller punching machine, this perforation machine production efficiency, product quality, perforation expansion diameter, can wear a variety of steel. After perforation, round tube billet has been three roll chrome, rolling or extrusion. After the extrusion to be detached. The sizing machine is rotated at high speed through the conical bit into the steel embryo to perforate to form the steel pipe. The inner diameter of the pipe is determined by the length of the outer diameter of the drill bit. After passing through the steel pipe, into the cooling tower, through the water cooling, steel pipe after cooling, it is necessary to straighten. After the steel pipe straightened by the conveyor belt sent to the metal testing machine (or water pressure test) for internal testing. If the steel pipe cracks, bubbles and other issues, will be detected. After the steel pipe quality inspection through rigorous hand selection. After the steel pipe quality inspection, Carbon Steel Pipe and Tube with paint spray on the number, specifications, production batch number. And hanging from the crane into the warehouse.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com