Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

The reducer is mainly composed of transmission parts (gears or worms), shafts, bearings, boxes and accessories. Its basic structure has three parts:

1. Gear, shaft and bearing combination

Pinion and shaft into one, called the gear shaft, this structure for the gear diameter and the diameter of the shaft is not related to the case, if the diameter of the shaft is D, gear tooth root circle diameter of DF, then when df-d鈮6~7mn, should use this structure. When DF-D>6~7MN is used, Reducer the gear and shaft are separated into two parts, such as low-speed shafts and large gears. At this point the gear and the axis of the circumferential fixed flat key joints, shaft parts using the shaft shoulder, sleeve and bearing cover for axial fixed. Deep groove ball bearings are used in both axes. This combination is used to withstand radial loads and minor axial loads. Reducer When the axial load is large, the combined structure of angular contact ball bearing, tapered roller bearing or deep groove ball bearing and thrust bearing should be adopted. The bearings are lubricated with a thin oil that is splashed when the gears are rotated. The lubricating oil in the tank seat is splashed into the inner wall of the lid by the rotating gear, Reducer and flows into the bearing through the guide oil trough after the inner wall is poured into the box-side groove. When the oil-immersed gear circumference speed 蠀鈮2m/s, should use lubricating grease lubrication bearings, in order to avoid the possibility of splashing dilute oil washed off the grease, can be separated by the oil retaining ring. In order to prevent the loss of lubricating oil and the outside dust into the box, the bearing end cover and the outer extension shaft are fitted with a sealing element.

The reducer is an independent closed-type transmission between the original motive and the working machine, which is used to reduce the speed and increase the torque to meet the needs of the work, Reducer which is also used in some occasions as the growth rate.

Performance characteristics

Reducer is a combination of deceleration motor and large reducer. No coupling and adapter, compact structure. The load is distributed on the planetary gears, thus carrying capacity is higher than the general helical gear reducer. Meet the need of high torque output in small space.

Widely used in large-scale mining, steel, chemical, port, Reducer environmental protection and other fields. With K, R series can get a greater speed ratio.

1, reliable industrial gear transmission components;

2, the reliable structure and a variety of inputs to adapt to the special requirements of use;

3, with high transmission power capacity and compact structure, Reducer gear structure according to the principle of modular design;

4, easy to use and maintenance, according to technical and engineering conditions to configure and select materials;

5, torque range from the beginning, 0000Nm to 1, and 000Nm.

The selection of reducer should be based on the selection of working conditions, technical parameters, power engine performance, Reducer economic factors such as comparison of different types of reducer of the external profile size, transmission efficiency, bearing capacity, quality, price, etc., select the most suitable reducer.

Load classification

The load state of the working machine connected with the reducer is more complicated, Reducer the impact on the reducer is very big, is the reducer selection and calculation of the important factors, the load state of the reducer (from the motive) of the load state, usually divided into three categories: 鈶-uniform load, 鈶-medium impact Load, 鈶-strong impact load.

Related News

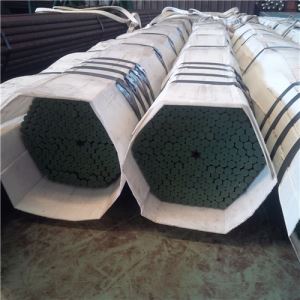

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com