Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

Basic Info

-

Model NO.: IR-B steel pipe

-

Technique: Hot Rolled

-

Surface Treatment: Polished

-

Section Shape: Round

-

Thickness: 8mm~40mm

-

Surface: Polished, Bare Pipe

-

Trademark: Iron&steel

-

Specification: ASTM A335

-

HS Code: 73045910

-

Type: Seamless

-

Material: Alloy Steel

-

Usage: Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose

-

Size: 114mm~810mm

-

Length: Fixed Length, by Random

-

End Processing: Plain Ends

-

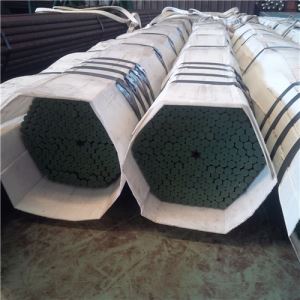

Transport Package: Standard Seaworthy Packing

-

Origin: China

Product Description

ASTM A335 P91 Alloy Seamless Steel Tube (Pipe)

We are supplying seamless alloy pipe with big diameter and wall thickness. This kind of alloy pipe are widely used at power plant, boiler industry, mechanical making, chemical plant, nuclear power industry, etc.

The manufacturer is Yangzhou Steel Pipe Co.,Ltd and TPCO.

Standard: ASME SA106, ASME SA335, ASME SA333, DIN17175, EN10216-2, GB5310, GB3087.

Steel grade: SA335 P11/P12/P22/P91/P92, WB36, 10CrMo910, 20G, 15CrMo, 12Cr1MoVG,

SA333 I, SA333VI, ST45.8/III,etc

Outer diameter: 219mm~1066mm

Wall thickness: 15mm~120mm

Professional Loading works

Tolerance of size of our seamless alloy pipe:

| Type of pipe | Outer diameter | Wall thickness | ||

| OD (mm) | Tolerance (mm) | WT (mm) | Tolerance (mm) | |

| Hot rolled pipe | 219~457 | 卤1.0% | 鈮20 | -10%~+12.5% |

| >20~40 | -10%~+10% | |||

| 457~1066 | 卤0.9% | >40~70 | -7%~+9% | |

| >70~120 | -6%~+8% | |||

Further more, the plant has large-scale cold rolling machine(by 1200t, 1600t, 2000t), the maximum cold rolling diameter

can be 920mm. Cold rolling technics can improve the precision of diameter and wall thickness. So we can supply high steel grade steel pipe with big diameter and thin thickness.

Our service

Make production according to customer's specific requirements strictly.

Accept inspection during the production or before shipment.

Provide the original copy of MTC(Mill testing certificate)

Provide the standard seaworthy packing.

Arrange the most professional shipment.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com