Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

Basic Info.

Model NO.:ZB-PT

Material:SUS304

Application:Screen, Filter, Protecting Mesh, Window Curtain

Type:Perforated

Other Material:Ss304L, Ss316, Ss316L

Other Hole Shape:Square, Diamond

Thickness:0.7mm-2mm

Place of Origin:China

Material Type:Stainless Steel Plate

Weave Technique:Perforated

Wire Mesh Width:as Ordered

Technique:Perforated

Nickels:10%

Certification:ISO9001

Trademark:ZB

Transport Package:Wooden Box

Specification:ISO9001

Origin:China

HS Code:73145000

Product Description

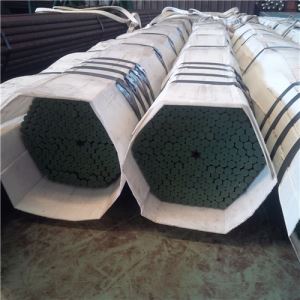

Stainless steel perforated metal tube - round/rectangular/diamond holes

Perforated metal tube is made of perforated metal mesh with a wide range of perforated patterns and open area percent. It can be made from a variety of materials including stainless steel plate, hastelloy plate and mild steel plate through punching and welding. The perforated metal tube can be punched in round hole, square hole, rectangular hole, hexagonal hole and special openings. And the welding type can be direct welding or screw welding. Because of its perforated structure, this type of filter can offer superior resistance to bending and crimping. So it is the ideal choice to be used where need rigidity and durability.

Advantages of stainless steel perforated tube

Stainless steel, unlike carbon steel, features rust resistance and corrosion resistant. It contains chromium, when exposed to oxygen, creates an invisible protective film. Stainless steel types are classified into three different groups based on their ability to be hardened. Austenitic stainless steel, which can be hardened by cold working condition, meets a wide range of design criteria.

Commonly Perforated Stainless Steel Types

304 (Austenitic)

One of the most widely used general-purpose stainless steels. It possesses an excellent combination of strength, corrosion resistance and fabricates well. To reduce carbide precipitation when welding, use 304L for its lower-carbon content.

316 (Austenitic)

Superior corrosion resistance compared to other 300 series alloys when used in used harsh corrosive environments (ex. sea water, chemicals, etc.). To reduce carbide precipitation when welding, use 316L for its lower-carbon content.

321 (Austenitic)

Titanium stabilized stainless steel to prevent intergranular formation of chromium carbide. It exhibits strength characteristics superior to those of 304 stainless, thus making it best suited for parts which cannot be subsequently annealed.

410 (Martensitic)

The lowest alloy content of the three general-purpose types. It is a heat-treatable chromium type used for highly stressed parts needing the combination of strength and corrosion resistance.

409 (Ferritic)

The lowest chromium content of the stainless steels, 409 combines good elevated temperature corrosion resistance with medium strength, good formability, and overall cost.

430 (Ferritic)

A general-purpose non-heat-treatable chromium type used for highly polished trim applications in mild atmospheres. Its strengths are in ductility, formability, good corrosion and oxidation resistance, thermal conductivity and finish quality.

Specification

Material: stainless steel mesh, hastelloy, mild steel.

Hole type: round hole, elliptical hole, square hole, rectangular hole, hexagonal hole or special openings.

Thickness: 0.2-15 mm.

Diameter: 6 - 169 mm.

Filter precision: 2 - 2000 渭m.

Welding type: direct welding or screw welding.

Packing: pallet or wooden boxes.

Gauge | Holes | Centers | Open Area % |

30 | .020" | .045" | 20% |

26 | 1/32" | 1/16" | 22% |

26 | .033" | .055" STRAIGHT | 29% |

24 | 3/64" | 3/32" | 23% |

26 | .050" | .066" STRAIGHT | 52% |

26 | 050" | 5/64" | 37% |

22 | 1/16" | 3/32" | 40% |

22,26 | 1/16" | 7/64" | 30% |

20,18 | 1/16" | 1/8" | 23% |

22,20 | 5/64 | 1/8" | 35% |

20,18,16 | 3/32 | 5/32" | 33% |

22 | .117 | 5/32" | 51% |

26-11 | 1/8 | 3/16" | 40% |

20-16 | 5/32" | 3/16" | 63% |

24-14 | 3/16" | 1/4" | 51% |

18,11 | 3/16" | 5/16" | 33% |

22-16 | 1/4" | 5/16" | 58% |

20-14,11 | 1/4" | 3/8" | 40% |

10 | 3/8" | 1/2" | 51% |

18,16,11 | 3/8" | 9/16" | 40% |

20,16,14,11 | 1/2" | 11/16" | 48% |

11 | 3/4" | 1" | 51% |

Features

Flat and smooth surface.

Durable and good strength.

Hard wearing, and easy to wash for reuse.

High dirt holding capacity.

Anti-acid, anti-alkali and anti-corrosion.

High reliable standard specifications

Applications

Perforated metal tube is widely used in petroleum, chemistry, metallurgy, machine, medicine, automobile industries for distillation, absorption, evaporation and filtration processes, so as to eliminate the impurity and foam mixed in the gas and liquid.

Filtration of liquid: ceramics polluted water cleaning, beverage, disposal of sewage water, filtration of corrosive liquids, beer brewing filter, etc.

Filtration of solid: glass, coal, food processing industry, cosmetics, fluidised beds, etc.

Filtration of oil: oil refining, hydraulic oil, oilfield pipelines, etc.

Filtration of other fields: textile industry, insulation industry, automotive industry, chemical industry, metallurgy, pharmacy, electronic field, etc.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com