Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

Basic Info

-

Model NO.: sinpower-xy33

-

Shape: Square

-

Temper: T3-T8

-

Alloy: Alloy

-

Alloying Ingredient: 6063

-

Polished Aluminum Profile: Chemical Polishing

-

Anodic Oxide Layer Thickness: AA10&AA15&AA20

-

Available Color: White/Golden/Silver/Steel/Bronze/Black

-

Trademark: SinPower Aluminium

-

Specification: GBT6892-2000

-

HS Code: 76042100

-

Type: Window & Door Aluminium Profile, Decoration Aluminium Profile, Glass Wall Aluminium Profile, Transport Aluminium Profile

-

Grade: 6000 Series

-

Window & Door Aluminium Profile: 90 Series

-

Surface Finishing: Anodic Oxidation

-

Certification: CE, ISO, TUV

-

Legnth: 3-12m

-

Processing: Extruded

-

Coating Selection: Electrophoresis&Powder Coating&Fluoropolymer

-

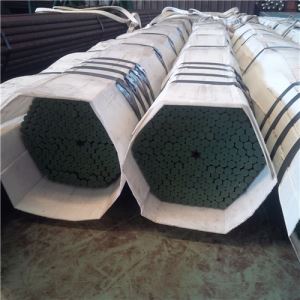

Transport Package: Borwn Paper with Plastic Film Wrapped

-

Origin: China

Product Description锛圔rief Introduction锛

Aluminum is a green material of choice. Aluminum's inherent "green features" of recyclability and sustainability, coupled with its other

unique attributes, make aluminum a versatile material for many applications, but the exciting story of aluminum doesn't stop here. The

ability to extrude aluminum into complex shapes (profile) gives designer creative freedom. Where the environment, time, cost and process repeatability are the important parameters, aluminum extrusions offer a material and process choice that is literally second to none for

countless product applications.

Extrusion Process

The aluminum extrusion process involves the use of a hydraulic press to force heated (still solid, but malleable) aluminum alloy through a

steel die. The resulting aluminum profile assumes the shape (in cross section) of the die opening.

Finishing

Aluminum profiles can be treated with a wide range of finishes wherever additional protection or an enhanced appearance is desired.

1. Mechanical Finishes are available in a variety of textures, produced by a variety of mechanical methods such as sanding, polishing,

grinding, buffing, or blasting.

2. Pretreatment refers to specific processes used to prepare the surface of the aluminum profile for subsequent finishing.

3. Chemical Finishes include etching, which yields a frosted surface appearance, and bright-dipping, which produce very shiny, specular

finish.

4. Anodizing is an electro-chemical process that forms a durable, porous anodic oxide layer on the surface of aluminum

5. Liquid Coatings include a broad range of paints such as polyesters, acrylics, siliconized polyesters, and fluoropolymers available in

virtually unlimited array of colors.

6. Powder Coatings provide a durable finish with little or no use of solvents; they are gaining use while volatile organic compounds

(VOCs) are problematic.11. Heat Sink

Exit and Quench Temperature Data for Selected 6xxx-Series Alloys

|

Alloy |

Min. Press |

Critical |

Critical Cooling RaTypical Tempers |

Cooling Time (sec) at Minimum Cooling Rate |

Cooling Time (sec) at Maximum Cooling Rate |

|

6003 |

930 |

2-3 |

840-480 |

180 (at 2 deg/sec) |

120 (at 3 deg/sec) |

|

6463 |

930 |

5 |

840-480 |

72 (at 5 deg/sec) |

72 (at 5 deg/sec) |

|

6063A |

930 |

3-5 |

840-480 |

120 (at 3 deg/sec) |

72 (at 5 deg/sec) |

|

6060 |

930 |

3-5 |

840-480 |

120 (at 3 deg/sec) |

72 (at 5 deg/sec) |

|

6101 |

930 |

3-5 |

840-480 |

120 (at 3 deg/sec) |

72 (at 5 deg/sec) |

|

6005A |

950 |

5-15 |

860-480 |

76 (at 5 deg/sec) |

25 (at 15 deg/sec) |

|

6061 |

950 |

10-20 |

860-480 |

38 (at 10 deg/sec) |

19 (at 20 deg/sec) |

|

6082 |

950 |

10-20 |

860-480 |

38 (at 10 deg/sec) |

19 (at 20 deg/sec) |

|

6351 |

950 |

10-20 |

860-480 |

38 (at 10 deg/sec) |

19 (at 20 deg/sec) |

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com