Product Categories

Contact Us

Wen zhou boxin steel industry Co., Ltd

Add:4102 Yong Qiang Avenue,Longwan District, Wenzhou. China

Tel:+86-577-86927958

Pho:+8618058896089

Fax:+86-577-86927988

E-mail:info@boxinsteel.com

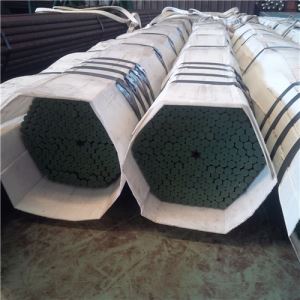

Processing and production of elbow materials must be qualified, there are deformation, cracks and other defects of the elbow bar, connectors and fasteners are strictly prohibited to use, elbow fasteners, connectors shall not be repaired by welding. Elbow easily out of the external arc wall thickness to reduce excessive, rebound super poor defects, Elbow the detailed method is as follows: When the elbow out of the external arc wall thickness thinning excessive, the main reason to reduce the phenomenon of excessive speed through the rapid. Extrusion: Is the elbow metal placed in the closed squeeze Jane, one end pressure, so that the metal from the designated mold hole extrusion and get the same shape and size of the finished product processing method, more used to produce non-ferrous metal elbow. The rebound is very bad, Elbow the elbow in the end of the bending and heat treatment will produce a certain amount of rebound. Generally divided into open and die forging, commonly used to produce large profiles, such as the opening of the section of the larger position of the material. Often used for a round-trip connection when a pipe is connected to a connection point that is not on the unified plane. Solution: heating temperature and speed strictly match, Elbow give a certain speed value, strictly according to the set speed control. The main processing methods of elbow are:

Different types of elbow have different quality function price ratio, used in different environmental conditions. No matter how high the elbow processing to do not agree with the situation. Simmer the form of elbow: the simmering elbow has good flexibility, high pressure resistance, small pipe wall smooth resistance and other advantages. Elbow in long transmission pipeline through many terrain complex, Elbow inclement weather conditions, therefore, in the pipeline laying the need to use a large number of elbows. The solution is to determine the resilience of a particular material and specification elbow by test, and when setting the bending radius, Elbow the rebound amount is calculated, and the appropriate offset or bending radius is set to increase the material length of the elbow base material. According to the elbow processing temperature not elbows with the cold processing and hot processing two kinds. The springboard on any elbow must be firmly fastened, with no larger holes on the platform surface (except for special parts). Curved pipe: Is the elbow with three bending angle, the middle is 900, the side angle is 135 degrees. Elbow Pull elbow: Is the rolling of the metal billet (type, tube, products, etc.) through the Die Broach dial into the section to reduce the length of the processing method is mostly used for cold processing.

Elbow is to change the direction of pipe fittings. According to the angle, there are 45掳 and 90掳180掳 three kinds of most commonly used, in addition to engineering needs also include 60掳 and other non-standard angle elbow. Elbow materials are cast iron, stainless steel, alloy steel, malleable iron, carbon steel, Elbow non-ferrous metals and plastics. The way to connect with the pipe is: direct welding (most commonly used) flange connection, Hot melt connection, fused connection, threaded connection and socket connection, etc. Elbow According to the production process can be divided into: elbow, stamping elbow, push elbow, casting elbow, butt welding elbow. Other name: 90 degrees elbow, right angle bend, love and bend, etc.

Related News

- ASTM A213 Seamless Stainless Steel Pipe/Tube...

- 50X50mm Hot-Dipped Galvanized Square Steel Pipe/Square Welde...

- Stainless Steel Tube for Weld Pipes...

- Stainless Steel Tube Purchase Skills...

- Alloy Steel Pipe High Temperature...

- Elbow Of Buying Skills...

- Stainless Steel Tubes Have Antioxidant Properties...

- Alloy Steel Tube Has Low Temperature Resistance Characterist...

- Excellent Performance Of Reducer...

- Carbon 40mm Seamless Steel Pipe /Tube...

Blue

Blue  info@boxinsteel.com

info@boxinsteel.com